Glass-Fused-to-Steel Technology is a leading solution combines the advantages of both materials — the strength and flexibility of the STEEL and highest corrosion resistance of the GLASS. The Glass fused to the Steel at 1500 — 1650 deg. F (800 — 900 deg. C), become a new material: GLASS-FUSED-TO-STEEL with perfect anti-corrosion performance.

YHR has developed high-strength TRS (Titanium Rich Steel) plates specially produced for the Glass-Fused-To-Steel Technology, which can work perfectly with our glass frit and can eliminates the “Fish Scale” defect.

GFS Tank Manufacturing Procedure

1. Raw Material

High-strength TRS (Titanium Rich Steel) plates specially produced for the GLASS-FUSED-TO-STEEL Technology.

2. Laser Cutting

Bolt holes and nozzle openings cut by full-automatic laser cutting to ensure more accurate and efficient production.

3. Shot Blasting

All plates shall be shot blasted to SSPC SP-10/NACE2 (Near White Metal) to remove the surface oxide layer and oil pollution.

4. Bending

The radian of the rolled plates shall be sampling inspected by using the radian sample according to the tank diameter.

5. Glass Coating

High quality glaze from Germany and advanced automatic spraying coating technology as per AWWA D103 standard.

6. Firing

GLASS FUSED TO STEEL — firing in automatic tunnel oven at 800 °C to make glass and steel combined absolutely.

7. Inspection

Adopted highest standard of quality control system in the industry, Holiday test and coating thickness test every plates.

8. Packing

Non-abrasive packaging sheets shall be placed between each plate to eliminate sheet-to-sheet abrasion during shipment.

Fusion Bonded Epoxy (FBE) is an electrostatically applied coating system with superior coverage and uniform coating thickness. AkzoNobel high-tech RESICOAT R4-ES used on the internal surface combined with the ultra durable INTERPON D2525 on the external surface ensures high performance corrosion resistance for storage tanks and silos. The internal coating RESICOAT R4-ES is NSF/ANSI 61 certified for drinking water contact, and the internal contact surface of every panels are zero defects tested at 1100v before delivering to the clients.

FBE Tank Manufacturing Procedure

1. Laser Cutting

Bolt holes and nozzle openings cut by full-automatic laser cutting to ensure more accurate and efficient production.

2. Shot Blasting

All panels shall be shot blasted to SSPC SP-10/NACE2 (Near White Metal) to remove the surface oxide layer and oil pollution.

3. Bending

The radian of the rolled plates shall be sampling inspected by using the radian sample according to the tank diameter.

4. Pre-treating

Degrease and rinse, then drying with convected warm air.

5. Pre-heating

Before coat application all panels should be pre-heating to ensure coating quality and thickness.

6. Epoxy Coating and Green Curing

Electrically applied thermoset resin fusion bonded epoxy coating on the internal surface, then cured at a controlled temperature.

7. Polyester Coating and Crosslink Curing

Evenly applied ultra durable polyester powder coating on the external surface, then cross-link cured to yield durable finished product.

8. Inspection and Packing

Holiday test and coating thickness test to every panel. Non-abrasive packaging sheets to place between each plate.

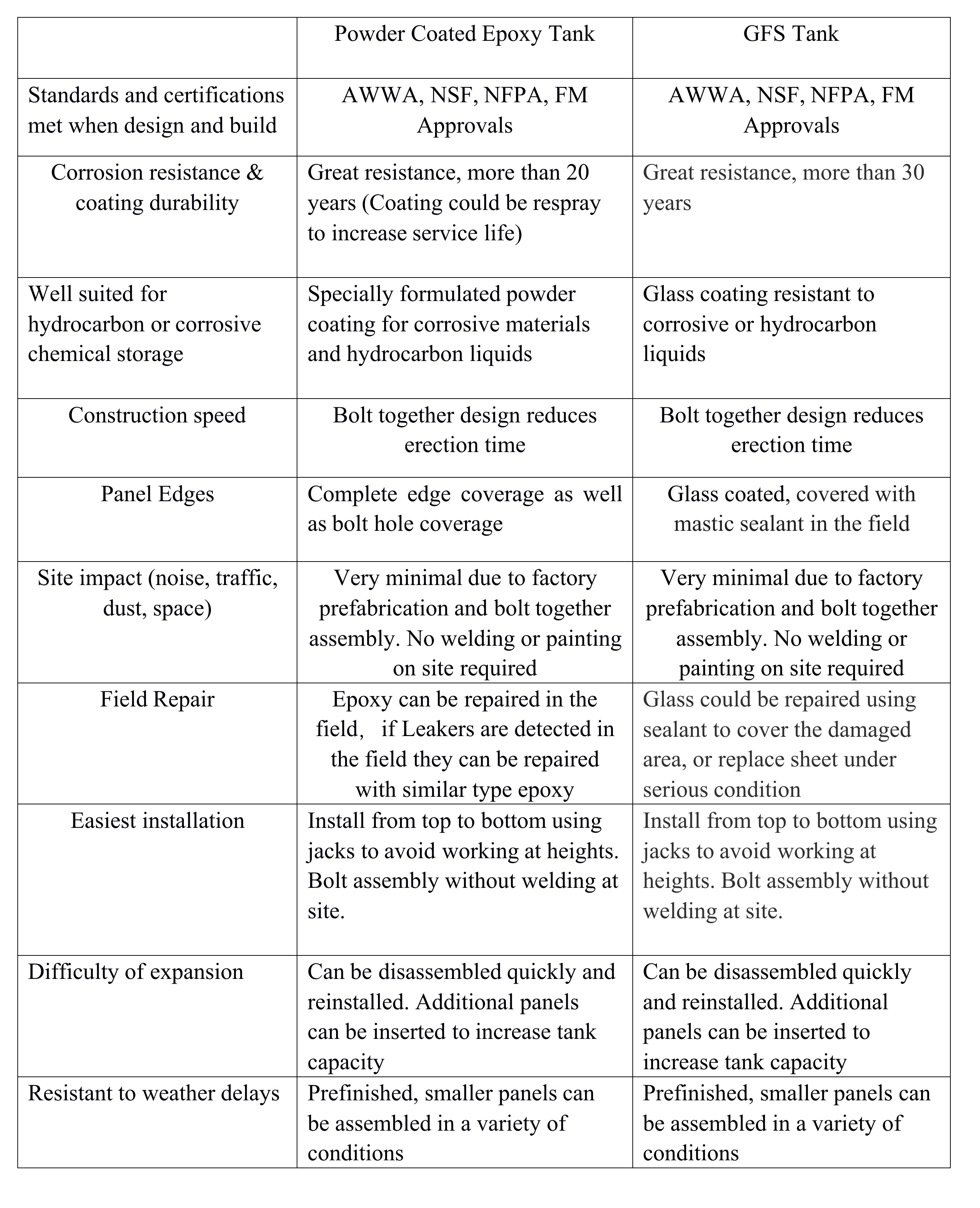

APPLICATION OF BOTH TANKS

1. Municipal Wastewater

2. Industrial Wastewater

3. Potable Water

4. Fire Protection Water

5. Biogas Digester

6. Slurry Storage

7. Sludge Storage

8. Liquid Leachate

9. Dry Bulk Storage

Post time: Jan-27-2022