High Capacity Glass Lined Steel Tanks Enamel Frit And Raw Steel Materials

Higher anti-corrosion YHR glass fused to steel tank using advanced manufacturing technology

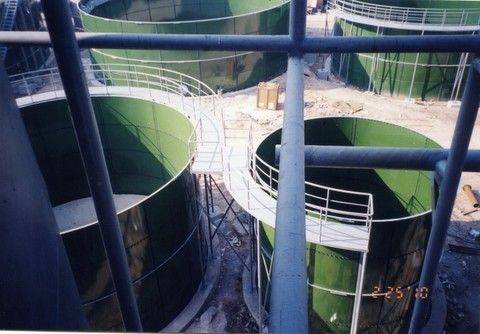

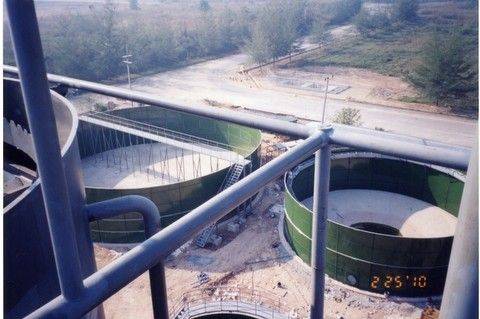

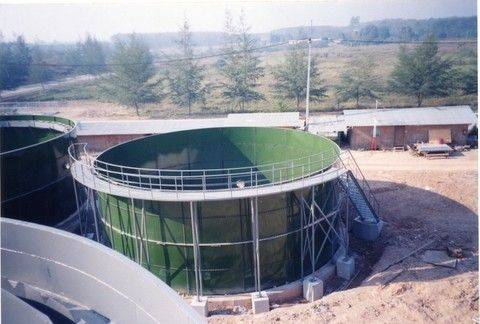

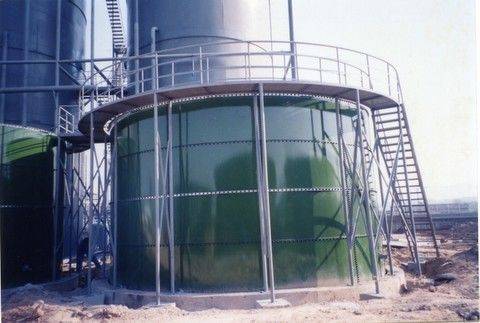

Glass-Fused-to-Steel / Glass-Lined-to-Steel

YHR Glass-Fused-To-Steel/Glass-LIned-Steel Technology, is a leading solution which combines the advantages of both materials – the strength and flexibility of the STEEL and high corrosion resistance of the GLASS. The Glass fused to the Steel at 1500-1650 deg. F, become a new material: GLASS-FUSED-TO-STEEL with perfect anti-corrosion performance.

YHR has developed high-strength TRS (Titanium Rich Steel) plates specially produced for Glass-Fused-To-Steel Technology, which can work perfectly with our glass frit and can eliminates the “Fish Scale”defect.

Comparison between GFS/GLS Tanks and Concrete Tanks

1. Easy Construction: All the tank shells of Glass-Fused-To-Steel Tanks are factory coated, can be easily assembled and installed in difficult conditions, to meet the urgency requirement of project, unlike Concrete Tanks will be affected seriously by bad weather and other factors.

2. Corrosion Resistance: Concrete tank would corroded through to reinforcing bar within 5 years of installation, Glass-Fused-To-Steel Tanks with 2 layer of Glass coating, can be applied for PH from 3 to 11, Center Enamel also provide 2 Years Warranty of its Glass-Fused-To-Steel Tanks.

3. Leakage and Maintenance: Concrete is susceptible to cracking so that many Concrete Tanks show signs of visible leaks and require substantial remedial maintenance, Glass-Fused-To-Steel Tanks are an excellent alternative with less maintenance due to the steel strong tension strength.

Specification

| Standard Color | RAL 5013 Cobalt Blue, RAL 6002 Leaf GreenRAL 6006 Grey Olive,RAL 9016 Traffic White,RAL 3020 Traffic Red,

RAL 1001 Beige (Tan) |

| Coating Thickness | 0.25-0.45mm |

| Double Sides Coating | 2-3 coats each side |

| Adhesive | 3450N/cm |

| Elasticity | 500KN/mm |

| Hardness | 6.0 Mohs |

| PH Range | Standard Grade 3-11; Special Grade 1-14 |

| Service Life | More than 30 years |

| Holiday Test | Acc. to tank application, up to 1500V |

Certification:

- ISO 9001:2008 Quality Control System

- ANSI AWWA D103-09 Design Standard

- Titanunum-Rich-Steel plates specially produced for GFS Techonogy

- Holiday Testing every panel at 700V – 1500V acc. to tank application

- Glass Coating Thickness every panel on both sides

- Fish Scale Testing (one test for one batch)

- Impact Testing for enamel adherence (one test for one batch)

- Chinese National High-tech Enterprise

- ISO 9001:2015

- NSF/ANSI/CAN 61

Advantages

- Excellent anti-corrosion performance

- Smooth, cohesionless, anti-bacteria

- Wear and scratch resistance

- High-inertia, high acidity / alkalinity tolerance

- Fast installation with better quality: design, production and quality contril in factory

- Less influenced by local weather

- Safe, skill-free: less working aloft, no need for long time worker training

- Low maintenance cost and easy to repair

- Possible to combine with other technologies

- Possible to relocate, to expand or to reuse

- Beautiful appearance

Company Introduction

YHR is a Chinese National High-Tech Enterprise. We started our research of Glass-Fused-To-Steel Technology since 1995 and built the first China-Made Glass-Fused-To-Steel Tank independently in 1999. Nowadays we are not only the leading Bolted Glass-Fused-To-Steel Tanks manufacturer, but also an integrated solution provider of biogas engineering. YHR is expanding oversea market rapidly, our Glass-Fused-To-Steel Tanks and equipment has been delivered to more than 30 countries.