Featured

-

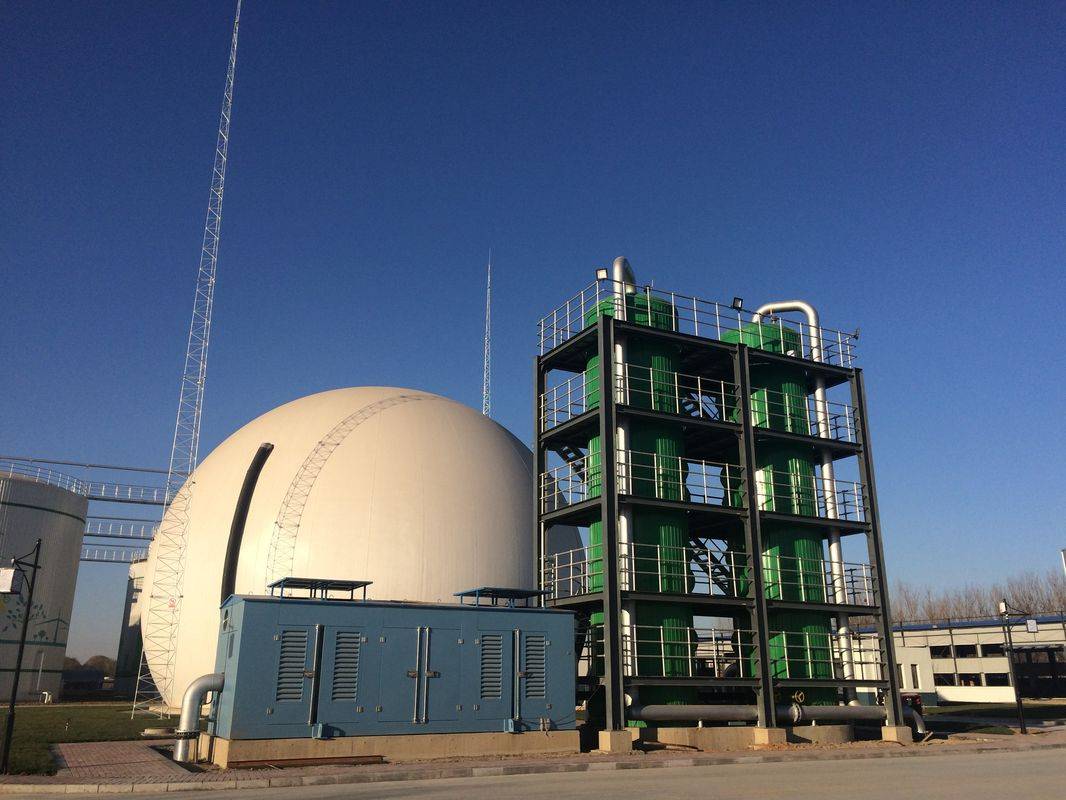

Free sample for Fire Sprinkler Tank - Hydrogen Sulfide Biogas Purification System Strong Exothermic Reaction – YHR

Detailed Product Description Type: Bolted Steel Tank Holiday Test: Up To 1500V Coat Thickness: 0.25-0.45mm Material: Glass-Fused-To-Steel High Light: biogas purification equipment , h2s removal system Chemical desulphurization, purification for biogas, H2S remove Hydrogen Sulfide (H2S) is a harmful impurity in biogas, to protect the biogas generator, CHP, biogas boiler and the pipeline from corrosion, H2S must be removed from the biogas. YHR has developed a series of desulphuriz... -

Free sample for Tank Epoxy - Gas Network 20 Bar Membrane Biogas Purification System – YHR

Detailed Product Description Biogenic Methane Index: Over 97% Methane Recovery: Over 96% Mode To Utilize Biomethane: CNG Or Gas Network Unit Energy Consumption: 0.15-0.25Kwh/Nm3 Methane Operating Pressure: Medium Or Low Pressure, 5-10/10-20 Bar Warranty: 2 Years High Light: 20 Bar Biogas Purification System , Membrane Biogas Purification System Biogas Upgrading System with Membrane for Biogas Purification Biogas Upgrading System Biogas is a renewable energy source and mostly ... -

High reputation Bolted Water Tank - Biogas Purification – YHR

Biogas Upgrading System Biogas is a renewable energy source and mostly produced from anaerobic digestion (AD). Biogas composition varies with the biomass digested and contains mainly methane (CH4) and carbon dioxide (CO2), as well as traces of hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), nitrogen (N2), carbon monoxide (CO), oxygen (O2). Membrane technology as purification process is a relatively recent but very promising technology. Also, hybrid processes where membranes are co... -

Manufacturer for Biodigester System - Biogas Purification – YHR

Biogas Upgrading System Biogas is a renewable energy source and mostly produced from anaerobic digestion (AD). Biogas composition varies with the biomass digested and contains mainly methane (CH4) and carbon dioxide (CO2), as well as traces of hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), nitrogen (N2), carbon monoxide (CO), oxygen (O2). Membrane technology as purification process is a relatively recent but very promising technology. Also, hybrid processes where membranes are co... -

Factory Free sample Elevated Steel Water Tank Design - Biogas Purification – YHR

Biogas Upgrading System Biogas is a renewable energy source and mostly produced from anaerobic digestion (AD). Biogas composition varies with the biomass digested and contains mainly methane (CH4) and carbon dioxide (CO2), as well as traces of hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), nitrogen (N2), carbon monoxide (CO), oxygen (O2). Membrane technology as purification process is a relatively recent but very promising technology. Also, hybrid processes where membranes are co... -

Best quality Egsb Reactor - Reliable Biogas Purification System Plug And Use 70 – 80 M2 / G Surface Area – YHR

Detailed Product Description Material: Glass-Fused-To-Steel Service Year: 30 Years Holiday Test: Up To 1500V Type: Bolted Steel Tank High Light: biogas purification equipment , h2s removal system Chemical desulfurization system/ H2S purification/ Plug and use Why we need desulphurization Removal of H2S is often required for reasons of health, safety, environment and corrosion of equipment such as gas engines, boilers and piping. Desulphurization is also is necessary when biogas ... -

Top Suppliers Non Potable Water Tank - Gas Network 20 Bar Membrane Biogas Purification System – YHR

Detailed Product Description Biogenic Methane Index: Over 97% Methane Recovery: Over 96% Mode To Utilize Biomethane: CNG Or Gas Network Unit Energy Consumption: 0.15-0.25Kwh/Nm3 Methane Operating Pressure: Medium Or Low Pressure, 5-10/10-20 Bar Warranty: 2 Years High Light: 20 Bar Biogas Purification System , Membrane Biogas Purification System Biogas Upgrading System with Membrane for Biogas Purification Biogas Upgrading System Biogas is a renewable energy source and mostly ... -

2021 China New Design Biogas Digester System - Explosion Proof Membrane Gas Holder Automatically Regulate ISO Approved – YHR

Detailed Product Description Capacity: 100~5000m3 Panel Thickness: 3mm~13mm Color: Dark Green, White, And Blue Size Of Panel: 2.4m X 1.2m High Light: double membrane gas holder , gas holder tank Ground Double Membrane Gas Holder Double-membrane gas holder is mainly used for storage of biogas. It is composed of external membrane, internal membrane and basement membrane. Air is tight between external membrane and internal membrane. The external membrane forms outer sphere shape fo... -

Fast delivery Stainless Water Storage Tank - Stable Biogas Purification System , Biogas Scrubbing System 0.7 – 0.75 Kg / L – YHR

Detailed Product Description Coat Thickness: 0.25-0.45mm Holiday Test: Up To 1500V Type: Bolted Steel Tank Material: Glass-Fused-To-Steel High Light: biogas purification equipment , h2s removal system Large scale biogas plant Chemical desulphurization system/ H2S purification Why we need desulphurization Removal of H2S is often required for reasons of health, safety, environment and corrosion of equipment such as gas engines, boilers and piping. Desulphurization is also is neces... -

Hot sale Double Membrane Roof - Aluminum Geodesic Dome Roof – YHR

Geodesic roofs are the newest roof type developed by YHR engineer which is designed to march perfectly with YHR Steel Bolted Tanks. This type of roof is widely used for Potable water storage, waste water treatment and dry bulk storage. Geodesic Roof is with the following advantages to make it ideal solution in many cases: Self-supporting The light weight of the material and the advantaged framing system enable YHR Geodesic roof to be self supported on the tank wall and no in-tank column is ne... -

Super Lowest Price Glass Lined Steel Tanks – Safety Liquid Fertilizer Storage Tanks , Steel Panel Tanks 6.0 Mohs Hardness – YHR

Detailed Product Description Material: Glass-Fused-To-Steel Type: Bolted Steel Tank Color: RAL5013 Cobalt Blue Coat Thickness: 0.25-0.45mm Service Year: 30 Years Holiday Test: Up To 1500V High Light: liquid holding tanks , water holding tank 30+ Years Service Life Liquid Storage Steel Tanks from 20m³ to 20,000m³ YHR Introduction YHR is a Chinese National High-Tech Enterprise with more than 200 employees. We started our research of Glass-Fused-To-Steel Techno... -

Reasonable price Potable Water Storage Tanks - Multifunction Biogas Purification System , Chemical H2s Scrubber – YHR

Detailed Product Description Holiday Test: Up To 1500V Coat Thickness: 0.25-0.45mm Type: Bolted Steel Tank Material: Glass-Fused-To-Steel High Light: biogas scrubbing system , h2s removal system Biogas desulfurization system/ H2S purification/ YHR scrubber Why we need desulphurization Removal of H2S is often required for reasons of health, safety, environment and corrosion of equipment such as gas engines, boilers and piping. Desulphurization is also is necessary when biogas is ...