Cheapest Price Sequential Batch Reactor Process - Gas Network 20 Bar Membrane Biogas Purification System – YHR

Cheapest Price Sequential Batch Reactor Process - Gas Network 20 Bar Membrane Biogas Purification System – YHR Detail:

Detailed Product Description

| Biogenic Methane Index: | Over 97% | Methane Recovery: | Over 96% |

|---|---|---|---|

| Mode To Utilize Biomethane: | CNG Or Gas Network | Unit Energy Consumption: | 0.15-0.25Kwh/Nm3 Methane |

| Operating Pressure: | Medium Or Low Pressure, 5-10/10-20 Bar | Warranty: | 2 Years |

| High Light: |

20 Bar Biogas Purification System, Membrane Biogas Purification System |

||

Biogas Upgrading System with Membrane for Biogas Purification

Biogas Upgrading System

Biogas is a renewable energy source and mostly produced from anaerobic digestion (AD). Biogas composition varies with the biomass digested and contains mainly methane (CH4) and carbon dioxide (CO2), as well as traces of hydrogen sulfide (H2S), ammonia (NH3), hydrogen (H2), nitrogen (N2), carbon monoxide (CO), oxygen (O2). Membrane technology as purification process is a relatively recent but very promising technology. Also, hybrid processes where membranes are combined with other processes are believed to have lower investment and operation costs compared with other processes.

Biogas Upgrading System Specification

- Biogenic Methane Index: Over 97% or recovered in bio natural gas quality

- Methane Recovery: Over 96%

- Mode to utilize Biomethane: CNG or Gas Network

- Unit Energy Consumption: 0.15-0.25 Kwh/Nm³ Methane

- Operating Pressure: Medium or Low Pressure, 5-10 or 10-20 Bar (According to the product configuration)

- Environmental Benefits: Minimum Greenhouse Gas Emissions

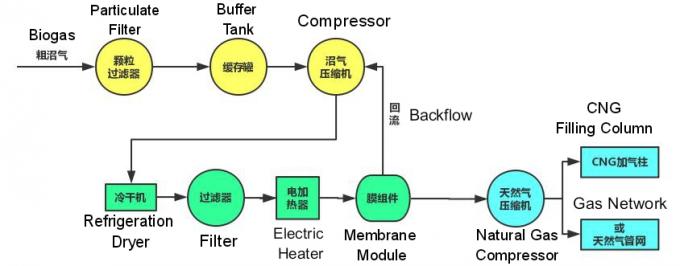

System Compostion

Pictures

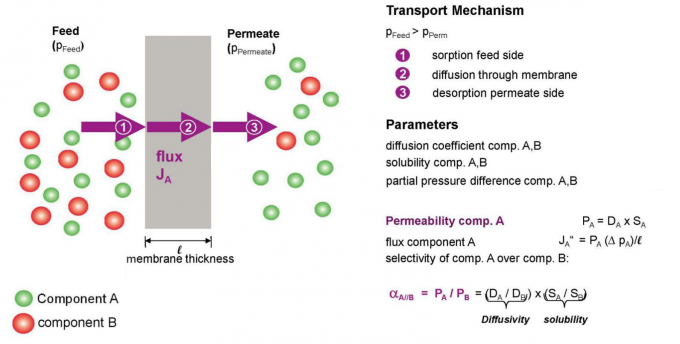

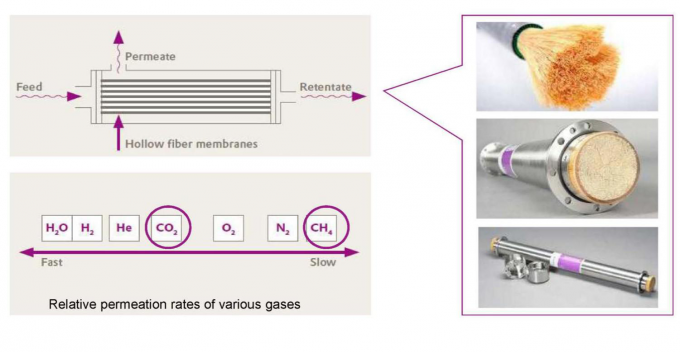

Membrane Technology

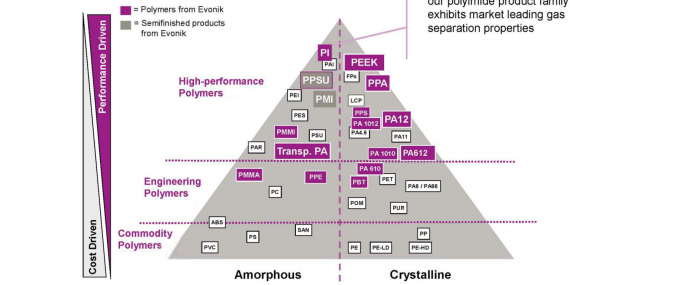

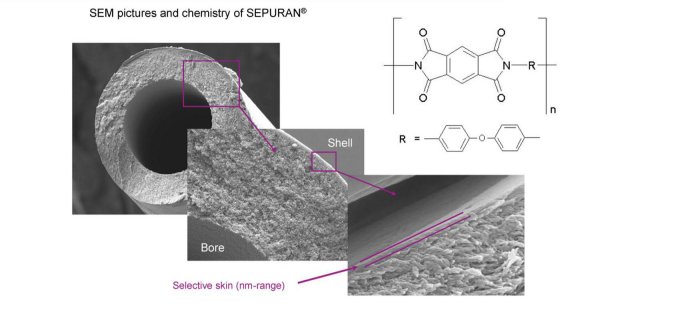

For the Membrane we choose EVONIK as our partner and membrane supplier. Their membrane upgrading process with SEPURAN® Green delivers a constant high biomethane grade with more than 99% purity. In other words, almost all the methane is recovered in bio natural gas quality.

Evonik has developed a biogas upgrading process that makes best use of the membranes' separation properties: Through skillful connection of SEPURAN® Green membranes it is possible to obtain methane with a purity level of up to 99% from the crude gas. Just one compressor is needed.

SEPURAN® Green membranes have the highest CO2/CH4 selectivity and are therefore a superior technology for upgrading biogas. This selectivity of the membranes enables the production of high purity biomethane with superior methane recovery. This distinguishes the Evonik membranes from other membranes that are available.

BENEFITS OF SEPURAN® GREEN MEMBRANE TECHNOLOGY

- Reduced operating costs

- Low Investment

- Easy to operate

- Low space requirement and short installation times

- Flexible and modular Installation

- No chemicals required

- No additional drying stage

Typical Configuration

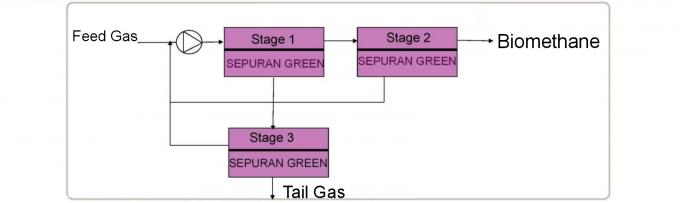

Three Stage Membrane Process — Medium Pressure

- Biogenic Methane Index: Over 97% or recovered in bio natural gas qualityMethane Recovery: Over 99%

- Mode to utilize Biomethane: CNG or Gas Network

- Unit Energy Consumption: 0.25-0.25 Kwh/Nm³ Methane

- Operating Pressure: Medium Pressure, 10-20 Bar

- Environmental Benefits: Minimum Greenhouse Gas Emissions

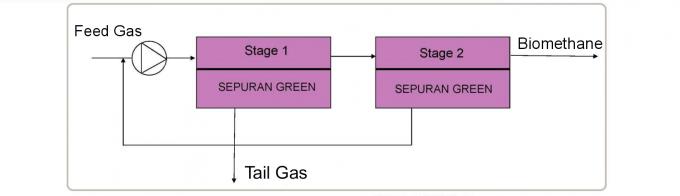

Two Stage Membrane Process — Medium Pressure

- Biogenic Methane Index: Over 97% or recovered in bio natural gas qualityMethane Recovery: Over 97%

- Mode to utilize Biomethane: CNG

- Unit Energy Consumption: 0.25-0.25 Kwh/Nm³ Methane

- Operating Pressure: Medium Pressure, 10-20 Bar

- Environmental Benefits: Lower Greenhouse Gas Emissions

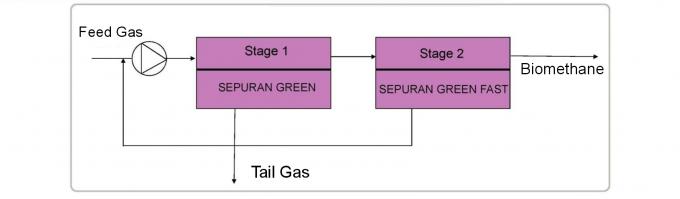

Two Stage Membrane Process — Low Pressure

- Biogenic Methane Index: Over 97% or recovered in bio natural gas quality

- Methane Recovery: Over 96%

- Mode to utilize Biomethane: Gas Network

- Unit Energy Consumption: 0.15-0.20 Kwh/Nm³ Methane

- Operating Pressure: Low Pressure, 5-10 Bar

- Environmental Benefits: Lower Greenhouse Gas Emissions

Company Profile

About YHR

YHR, a high-tech enterprise, is committed to the R&D and promotion of resourcefully utilizing agricultural organic waste, livestock and poultry wastewater treatment and anaerobic technology for high-concentration organic wastewater. As a domestic leading biogas engineering contractor, the company also acts as a benchmark enterprise in China's Glass-Fused-to-Steel Tanks industry. Providing design, production, installation, sales and commissioning services for complete-set environmental protection equipment including Glass-Fused-to-Steel Tanks, anaerobic reactors, biogas gas storage tank, biogas desulfurization equipment, biogas upgrading system, etc. for the sewage treatment sector and biomass biogas, YHR has developed itself steadfastly. YHR will always strive for the construction of beautiful countryside.

Product detail pictures:

Related Product Guide:

Cheapest Price Sequential Batch Reactor Process - Gas Network 20 Bar Membrane Biogas Purification System – YHR , The product will supply to all over the world, such as: , , ,