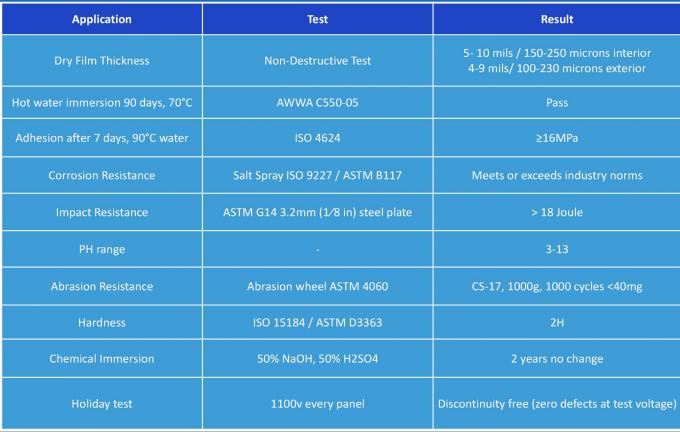

Anti Impact Epoxy Coating FBE 16MPa Liquid Storage Tanks

Detailed Product Description

| Dry Film Thickness(interior): | 5- 10 Mils / 150-250 Microns | Dry Film Thickness(exterior): | 4-9 Mils/ 100-230 Microns |

|---|---|---|---|

| Hot Water Immersion 90 Days, 70°C: | Pass | Adhesion After 7 Days, 90°C Water: | ≥16MPa |

| Corrosion Resistance: | Meets Or Exceeds Industry Norms | Impact Resistance: | > 18 Joule |

| PH Range: | 3-13 | Abrasion Resistance: | CS-17, 1000g, 1000 Cycles <40mg |

| Hardness: | 2H | Chemical Immersion: | 2 Years No Change |

| Holiday Test: | Discontinuity Free (zero Defects At Test Voltage) | ||

| High Light: |

16MPa Liquid Storage Tanks, FBE Liquid Storage Tanks, 2H Epoxy Coated Steel Tank |

||

Economical YHR fushion bonded epoxy coated steel tank fast installation large capacity for water harvesting

YHR Epoxy Tanks Technology

Fusion Bonded Epoxy (FBE) is an electrostatically applied coating system with superior coverage and uniform coating thickness. Epoxy coating is the economical solution which ensures high performance corrosion resistance for storage tanks. All epoxy coated panels are finished in YHR's ISO 9001 certified factory before delivered to the clients.

Specification

Advantages

- Excellent anti-corrosion performance

- Flexibility, superior impact-resistance

- 100% coating coverage on panel edges and holes

- Fast installation with better quality: design, production and quality control in factory

- Safe, skill-free: less working aloft, no need for long time worker training

- Less influenced by local weather

- Long life time

- Low maintenance cost and easy to repair

- Possible to relocate, expand and reuse

- Beautiful appearance

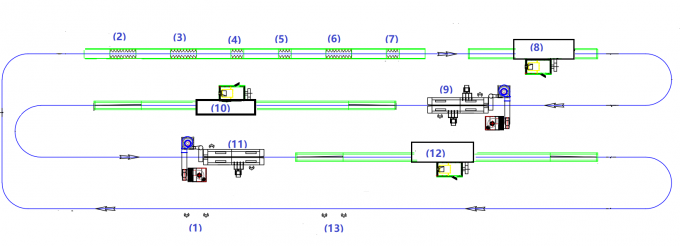

Production Procedure

- Hanging

- Degrease and Rust Removal

- Degrease

- 1st wash

- 2nd wash

- Silicohydride treatment

- 3rd wash

- Dry

- Base coat- epoxy coating

- Base coat cured

- Top coat-polyester coating

- Top coat cured

- Cool down and take off

Quality Control System

- 1100V Holiday Test every panel

- Coating Adhesion Test

- Dry Film Thickness Test on both sides

- Mechanical Properties Test each batch

- Color Compare Test each batch

- Wet Sponge Test if required

Certification

Pictures

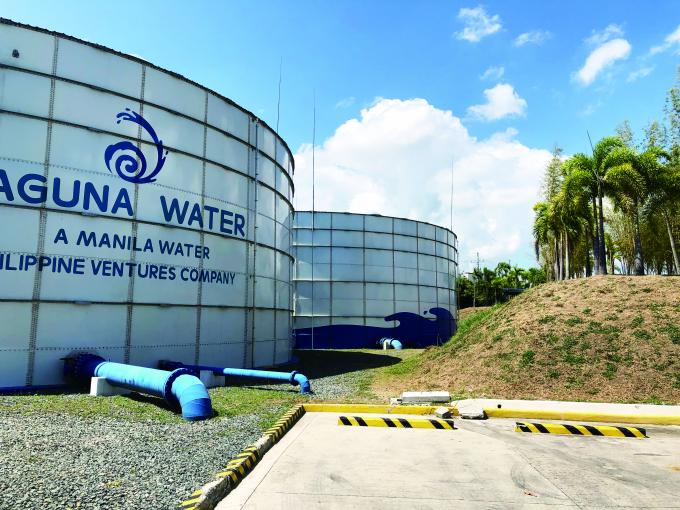

Company Profile

Beijing Yingherui Environmental Technology Co., Ltd (as known as YHR) is a Chinese National High-Tech Enterprise with more than 300 employees. YHR is the industry leading designer, manufacturer and erector of Bolted Storage Tanks.

YHR provides Bolted Glass-Fused-To-Steel Tanks, Fusion Bonded Epoxy Coated Steel Tanks and Bolted Stainless Steel Tanks for Liquid and Dry Bulk Storage solution.

2-168x300.jpg)